-

Lithium-ion batteries – electrolytes – solid & semi-solid

-

Ionic liquid monomer 1-(4-vinylbenzyl)-3-butylimidazole bis(trifluoromethanesulfonyl)imide ([VBBIM][TFSI]) and

polyethylene glycol diacrylate (PEGDA) monomer were dissolved in N,N-dimethylformamide (DMF), followed by

stirring (2 h) and the addition of cage-like silsesquioxane with olefin side-chains (POSS, 1 mass% relative to the total mass of LiTFSI, [VBBIM][TFSI],

PEGDA). Photoinitiator 1173 (1 mass% relative to [VBBIM][TFSI] and PEGDA) was then added, resulting in a crosslinked solid polymer electrolyte

membrane precursor solution.

This solution was coated on a copper-lithium composite tape (8 μm Cu, double-sided 10 μm Li) using a scraper, followed by

UV-curing (2-5 min), vacuum-drying (60°C, 12 h) and cutting.

The resulting polymer-coated negative electrodes were laminated with Li2MnO3-based positive electrodes to produce

1.5 Ah cells that exhibit a 1st cycle efficiency of 89.9% and a capacity retention after 200 cycles of 99.0%

(0.2 C charge / 1 C discharge, voltage window: 2.8-4.35 V).

This work illustrates how the combination of a cage-like silsesquioxane architecture cross-linked to an ionic liquid

polymer enables highly stable cycling of lithium metal electrodes and Mn-rich, Li2MnO3-based positive electrodes.

Presumably, very stable cycling was achieved because of favorable mechanical stability of the polymer layer in combination with

a favorable ion conductivity along nano-channels, a uniform current density distribution, and a stable interface with

minimal SEI-formation after the 1st cycle.

It will be interesting to see if faster charging is feasible, possibly upon reducing the solid electrolyte layer thickness (thickness not

disclosed in the patent application).

-

The premium version includes another two patent discussions, plus an Excel list with 50-100 commercially relevant recent patent families.

-

Lithium-ion batteries – positive electrode

-

A coating solution based on zirconium(IV) tetrapropoxide and an undisclosed lithium-ion source in ethanol

(1 : 1 molar ratio) was sprayed onto polycrystalline LiNi0.8Co0.12Mn0.08O2

using a fluid coating device (MP-01, POWREX, nitrogen gas intake temperature: 80°C, rotation

speed: 400 rpm), followed by a heat treatment (300°C, 2 h, oxygen).

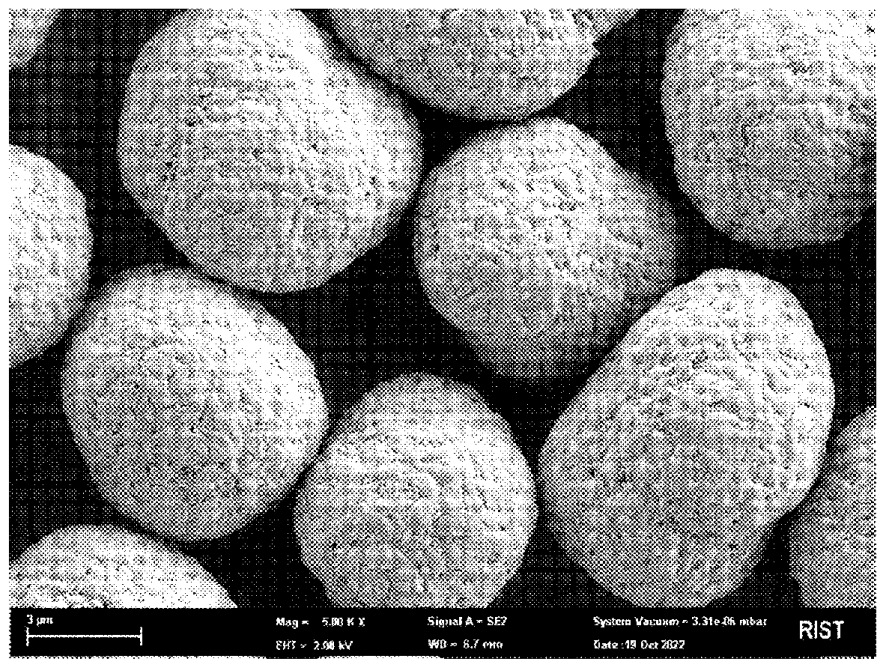

The resulting material (see SEM image below) exhibits a Li2ZrO3 coating layer weight of 0.4-1 mass%.

Positive electrode formulation: coated NMC prepared above / Li6PS5Cl / conductive carbon black (Super C65, IMERYS) =

75 : 22 : 3 by mass.

In half-cells with a Li6PS5Cl layer, these electrodes exhibit a discharge capacity of 206 mAh/g, a first cycle efficiency

of 92.8% and a capacity retention after 30 cycles of 98.3% (0.5 C charge / discharge), as compared to 194.8 mAh/g, 89.7% and 89.4% for comparative cells

with uncoated NMC.

This work illustrates that a Li2ZrO3 coating layer on NMC improves electrochemical characteristics in

sulfide all-solid-state cells.

-

The premium version includes another two patent discussions, plus an Excel list with 50-100 commercially relevant recent patent families.

-

Lithium-ion batteries – negative electrode (excluding Li metal electrodes)

-

ANODE MATERIAL FOR LITHIUM ION CELL

Applicant:

POSCO HOLDINGS / RESEARCH INSTITUTE OF INDUSTRIAL SCIENCE & TECHNOLOGY /

WO 2024128845 A1

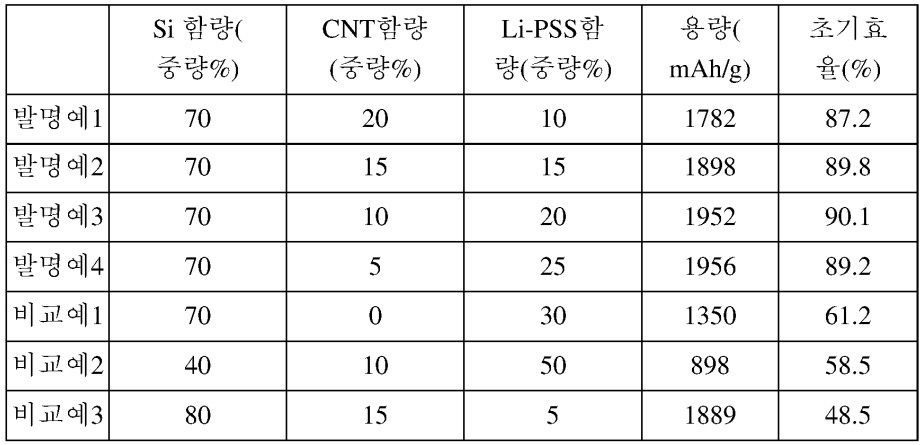

Si particles with a particle size distribution between 30 and 200 nm (average particle size: >50 nm)

were produced using wet grinding in ethanol or isopropanol,

followed by mixing with lithium polystyrene sulfonate (Li-PSS) and CNT (carbon nanotubes) in THF, spray-drying,

and a heat-treatment (200-300°C). As shown in the Table below, active material particles with various compositions were produced

and tested in half-cells (negative electrodes with polyacrylic acid binder).

초기효율: initial efficiency

용량: capacity

Li-PSS 함량: Li-PSS content

CNT 함량: CNT content

Si 함량: Si content

중량%: mass%

발명예: invention example

비교예: comparative example

This work illustrates how lithium polystyrene sulfonate (Li-PSS) reduces first cycle irreversible losses in Si-CNT composite materials.

No cycling stability data was disclosed.

-

The premium version includes another two patent discussions, plus an Excel list with 50-100 commercially relevant recent patent families.

-

Fuel cells (PEMFC / SOFC / PAFC / AEMFC) – electrochemically active materials

-

Optimized carbon support parameters were identified that minimize the Pt catalyst layer thinning rate

during a durability test, according to SEM measurements (usage of Nafion ionomer, PTFE base material, no differentation

between anode and cathode layers was disclosed, no details disclosed for durability test).

The carbon support material that leads to the lowest thinning rate exhibits a BET specific surface area

of ≈1,000 m2/g, a particle size of ≈350 nm, and a bulk density of ≈0.06 g/mL.

This work underlines the importance of fine-tuning carbon support properties to reduce the rate of catalyst deactivation in PEMFC cells.

-

The premium version includes another two patent discussions, plus an Excel list with 50-100 commercially relevant recent patent families.

-

Triweekly patent lists for other categories (Excel files are included for premium users)

-

- Lithium metal containing batteries (excluding Li-S, Li-Air): XLSX

-

- Lithium-ion batteries – electrolytes – liquid: XLSX

-

- Lithium-ion batteries – separators: XLSX

-

- Lithium-sulfur batteries: XLSX

-

- Metal-air batteries: XLSX

-

- Na-ion batteries: XLSX

-

Prior patent updates

-

2024-06-18

-

2024-05-28

-

2024-05-07

-

2024-04-16

-

2024-03-26

|