-

Key Developers

-

Key Developers Overview

-

The section on key developers will cover each of the ≥35 companies that make the final selection based on early subscriber feedback.

For each company, the patent literature is reviewed and the possible composition of future polymer membrane fuel cells will be highlighted.

The unique capability of each of the companies and potential roadblocks will be outlined.

Example – Extract for Heraeus – Germany

Organisation profile

Heraeus (https://www.heraeus.com,

catalyst product pages – fuel cells,

electrolysers), based in Hanau (Germany)

provides precious metal and specialty metal products to the energy,

electronics, environmental, health, mobility and industrial sectors. It provides catalyst powders for PEM electrodes.

Innovation profile

6 new patent families by Heraeus related to ‘PEMFC / AEMFC – electrochemically active materials’ have been published between 2021 and 2025-11-28.

These patent families are largely consistent with the Heraeus PEM fuel cells

catalyst portfolio, which accommodate various

requirements in terms of catalytic activity, stability, and cell reversal tolerance.

Key inventions towards improved catalyst activity:

-

use of carbon or TiO2 support materials with controlled BET surface area and pore size distribution.

-

oxygen plasma treatment of carbon support materials that have been produced in-house or were sourced externally (Vulkan carbon black). Favorable dispersion of the carbon support in water is likely of key importance towards achieving a homogeneous catalyst distribution on its surface.

-

careful adjustment of pH and other process conditions during catalyst precursor deposition and reduction.

-

careful optimization of heat treatment after depositing the catalyst on the support material, and after depositing the supported catalyst on the polymer membrane.

Figure 3 illustrates how Heraeus’ IP covers substantial vertical integration, including preparation of the carbon catalyst support,

metal precursors and preparation of catalyst-coated membranes (CCM).

Figure 3: projected manufacturing process for Heraeus

Unique capability: clear focus of R&D resources on catalysts, while controlling all process steps that can affect performance and costs.

Potential roadblock: none identified.

Possible composition of future catalyst products

-

FC: Pt on plasma-treated porous carbon (produced in-house, Figure 4) or plasma-treated carbon black (e.g. Vulcan XC72-R by Cabot).

Examples from the patent portfolio

A) PEM Catalysts

-

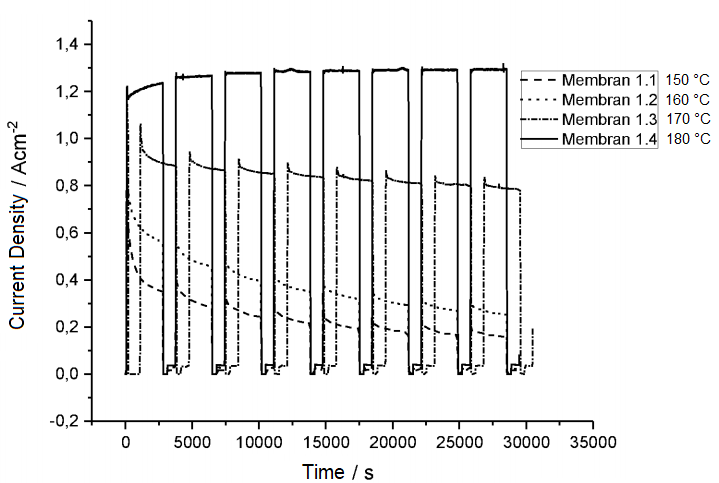

METHOD FOR PRODUCING A CATALYST-COATED MEMBRANE: an aqueous solution was prepared based on an ionomer of tetrafluoroethylene and a perfluorinated vinyl ether containing

sulfonic acid groups (MX820.15, Gore, 4.05 mass%) along with a catalyst deposited on a carbon support (7.19 mass%). The CCM was

heat treated at different temperatures (see Figure 4 below).

The thermal treatments lead to a significant increase in performance in humid operating conditions

and to a stabilization of performance that does not only start after several cycles, but very early. A so-called “pre-conditioning”

or “break-in” step for activating the membrane can therefore be omitted.

Figure 4: electrochemical performance of CCM upon heat treatment for 4 min at 150-180 °C

-

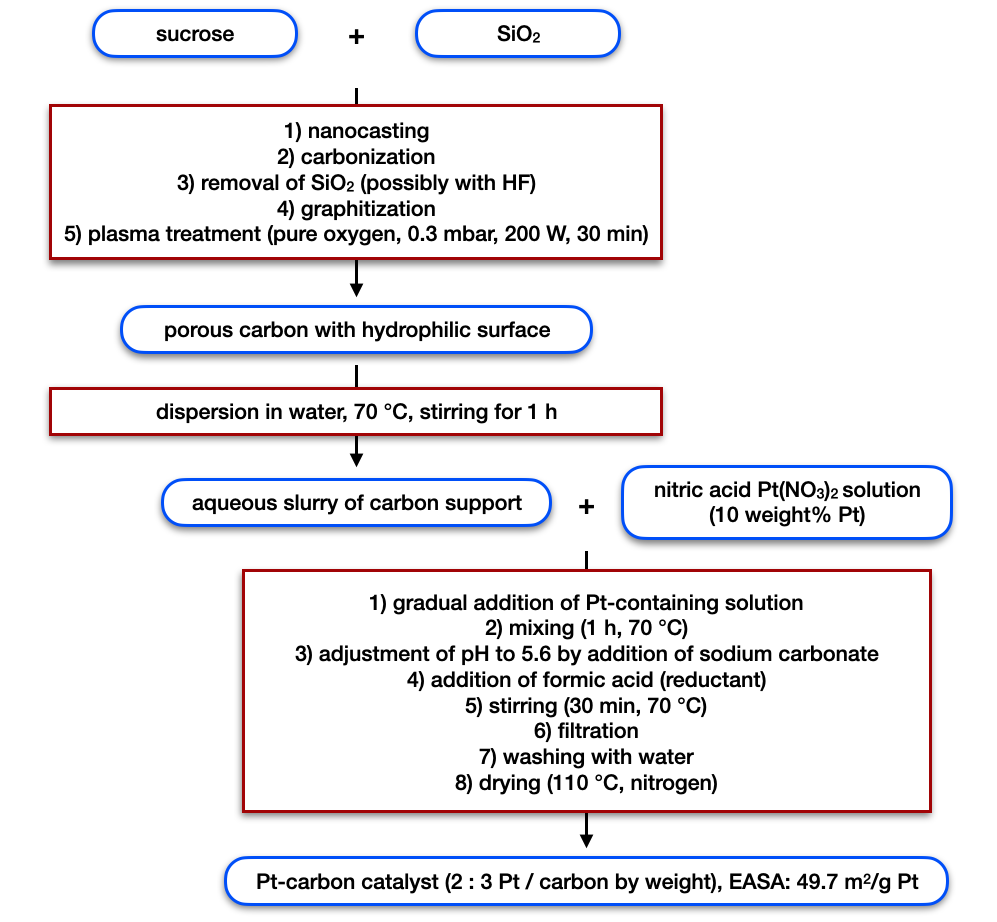

HIGH STABILITY CATALYST FOR AN ELECTROCHEMICAL CELL: a graphitized porous carbon material was produced via nanocasting by impregnating a porous SiO2 template with sucrose

(Figure 4), followed by carbonization, removal of SiO2 and graphitization of the carbonized material. This material was treated

with plasma (pure oxygen, 0.3 mbar, 200 W, 30 min). The resulting material was suspended in water at 70 °C. After 1 h, nitric acid

platinum nitrate solution (10 mass% Pt) was gradually added (2 : 3 Pt / carbon support by weight) and further mixed for 1 h. The pH

was then adjusted to 5.6 by adding sodium carbonate, followed by the addition of formic acid as reducing agent. After 30 min, the

Pt-carbon catalyst was filtered off, washed with water and dried (110 °C, nitrogen). This material exhibits an electrochemically

active surface area (EASA) of 49.7 m2/g Pt.

This work illustrates how a plasma treatment of the carbon support material leads to a substantial increase in the EASA,

which allows for a favorable balance between current density and longevity. This EASA value and product features are

consistent with commercially available Heraeus PEM FC catalysts.

-

METHOD FOR PRODUCING SUPPORTED PLATINUM PARTICLES: in a similar procedure as in the prior patent, Pt was deposited on conductive carbon black (Vulcan XC72-R by Cabot,

BET specific surface area: 250 m2/g) with H2PtCl6 in water at 70 °C, followed by the

addition of sodium carbonate to adjust

the pH value to 5.1 and reduction with formic acid. This material exhibits an EASA of 65 m2/g Pt.

This work illustrates how the EASA was further increased by employing a conductive carbon black support material.

Whether or not the increased BET specific surface area as compared to the carbon support in the prior patent (ca.

240 m2/g vs. ca. 60 m2/g) can be tolerated depends on stability and cell reversal tolerance requirements.

This EASA

and product features are consistent with

commercially available Heraeus PEM FC catalysts.

|