-

Lithium-ion batteries – electrolytes – solid & semi-solid

-

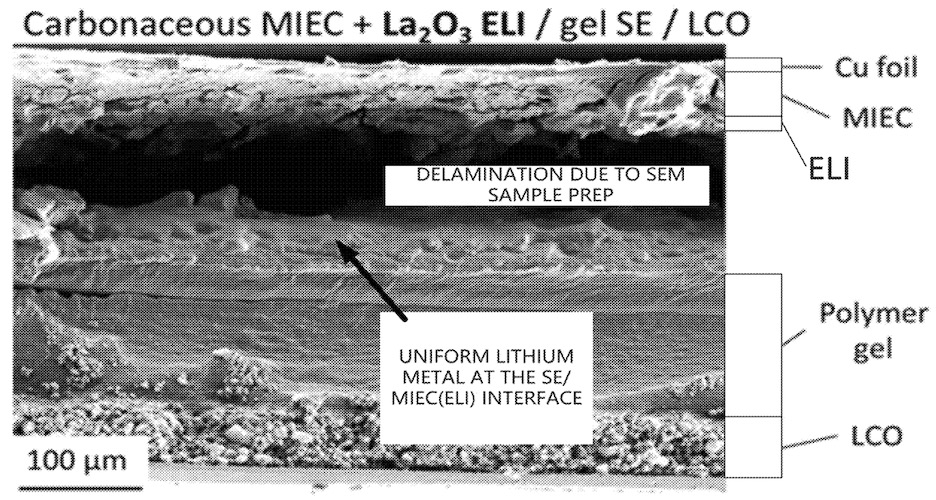

To form a negative electrode that allows for cycling of lithium metal, a carbon black / PVDF (polyvinylidene fluoride)

slurry was applied to a Cu foil, which resulted in a 5 μm thick porous MIEC (mixed ionic-electronic conductor) layer (see Figures below).

This negative electrode was heated to 300°C, and lanthanum nitrate (La(NO3)3) was spray-pyrolyzed onto it,

forming a 30 nm thick La2O3 ELI (electrolyte-layer integration) buffer layer

without post annealing.

A gel solid electrolyte was made using a PVDF-HFP (poly(vinylidene fluoride-co-hexafluoropropylene))

matrix with lithium bis(pentafluoroethanesulfonyl)imide in a 1:1 mass ratio mix of ethylene carbonate

and propylene carbonate. This electrolyte, about 300 μm thick, was layered onto the buffer layer at ambient

temperature. A 100 μm thick LiCoO2 (LCO) layer formed the positive electrode, completing the coin cell assembly.

Impedance measurements across 50 cycles (0.5 C charge / discharge) illustrate no significant increase, as compared to an increase of several orders of magnitude for

a comparative example without La2O3 layer.

FEW UM = few micrometers (about 5 μm as described above)

This work illustrates how the combination of a porous carbon black scaffold on copper covered by a La2O3 layer allows for cycling of lithium

metal negative electrodes with promising cycling stability (a larger number of larger-scale experiments is a necessary next validation step).

The gel solid electrolyte can probably be replaced with a liquid carbonate-free semi-solid or solid electrolyte layer to achieve an improved inherent safety

profile.

From a process cost perspective, this work is very significant because high-temperature sintering above 300°C has been avoided. The need for producing

and handling a free-standing oxide film was avoided by employing a spray-pyrolization process.

It is a very interesting question if La-free oxides based on highly abundant elements exhibit similarly favorable

characteristics as La2O3.

-

The premium version includes another two patent discussions, plus an Excel list with 50-100 commercially relevant recent patent families.

-

Get a quote to make better informed decisions.

-

Lithium-ion batteries – positive electrode

-

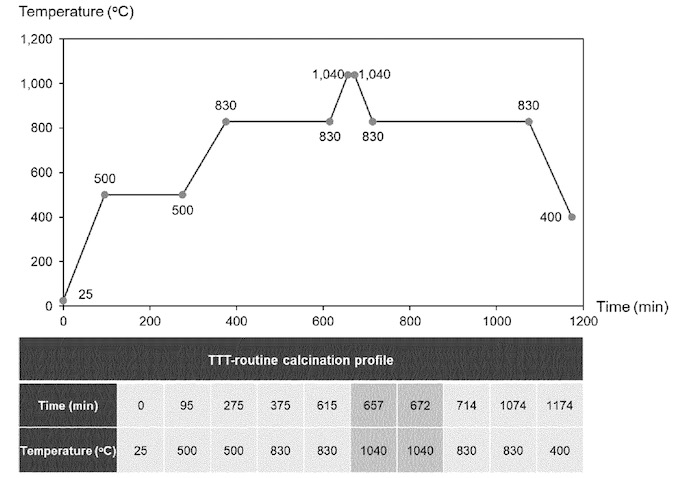

LiNi0.90Co0.05Mn0.05O2 (NMC9½½) was synthesized from the corresponding hydroxide precursor

and Li2CO3 using the temperature protocol shown in the top Figure that involves process steps at 500, 830 and 1,040°C.

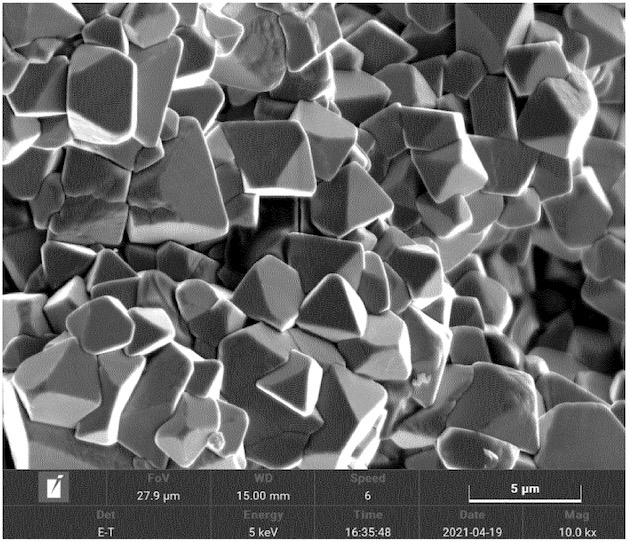

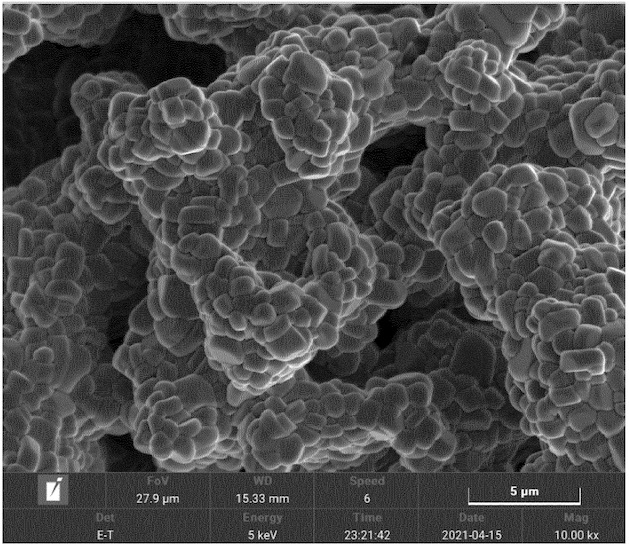

The middle Figure exhibits a SEM image of the corresponding NMC9½½ that illustrates well-defined crystallites, as compared to a comparative material

(bottom Figure) prepared without the so-called transient thermal treatment (TTT) step at 1,040°C for 15 min (formation of rounded, smaller domains).

While no electrochemical data is shown, the following advantages of single-crystal as compared to polycrystalline NMC materials are emphasized in the patent:

reduced structural deterioration, electrolyte side reactions and gas generation.

This work illustrates how a comparably short (15 min) high-temperature calcination step at 1,040°C very substantially affects NMC9½½ crystallinity

and presumably allows for benefiting from the advantages of single-crystal NMC without significantly increasing process costs.

-

The premium version includes another two patent discussions, plus an Excel list with 50-100 commercially relevant recent patent families.

-

Get a quote to make better informed decisions.

-

Lithium-ion batteries – negative electrode (excluding Li metal electrodes)

-

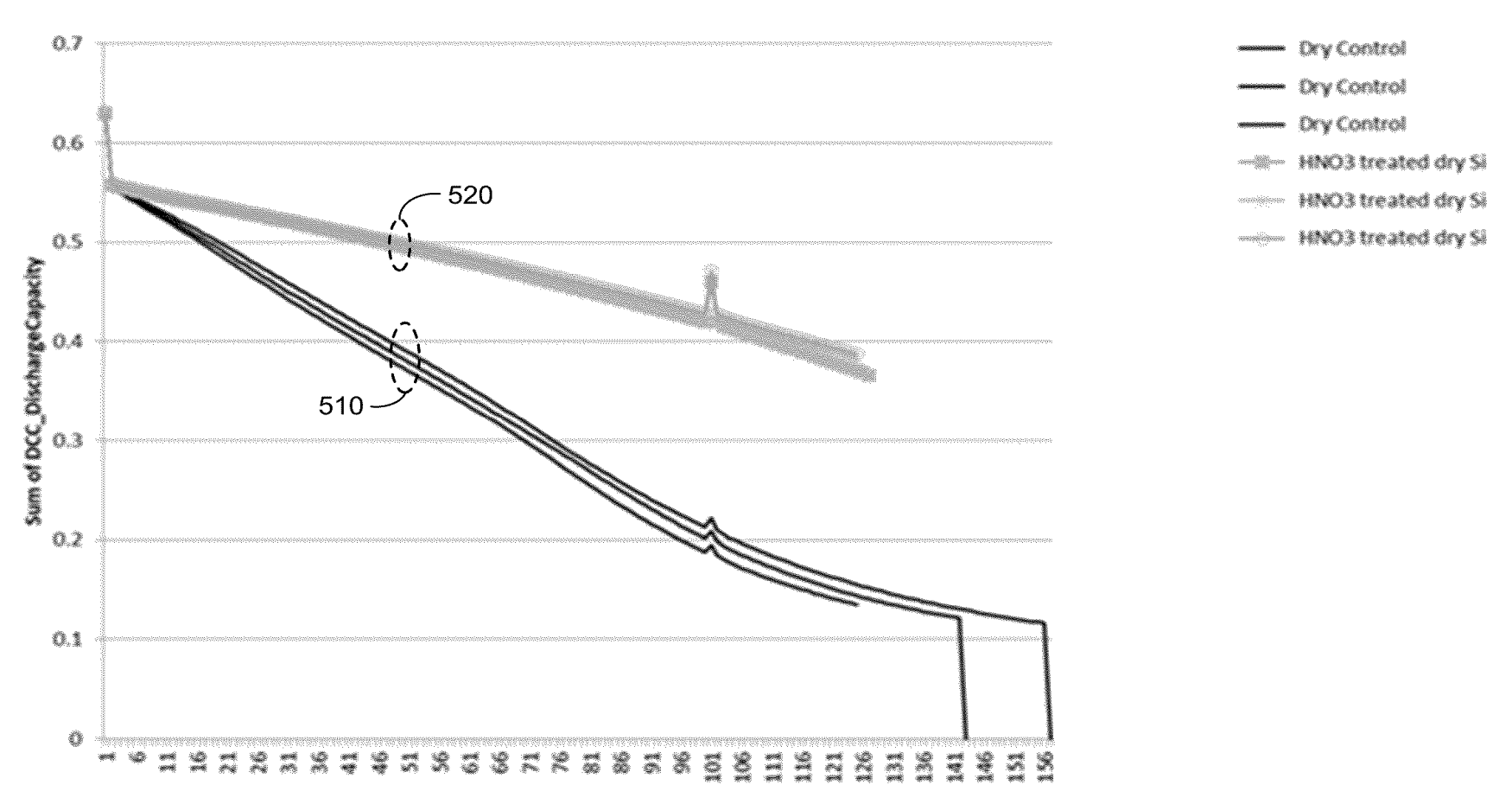

Silicon powder with an average particle size of about 20 µm was dispersed in 67% nitric acid for about 1 h, filtered and rinsed with water to remove any residual acid.

This treatment results in the formation of a surface oxide layer (<100 nm thickness).

Negative electrodes were built by dispersing treated silicon in a slurry with NMP (N-Methyl-2-pyrrolidone)

and polyamic acid resin, followed by coating on PET (polyethylene terephthalate) film, densification with a calender,

removal of the free-standing electrode from the PET foil, cutting, vacuum drying (120°C for 15 h, 220°C for 5 h),

and a thermal treatment (1,175°C) to carbonize the polymer.

The Si-carbon electrode was laminated with polyamide-imide-coated Cu foil to form electrodes for which the electrochemical test results

shown below were obtained (comparison of electrodes based on acid-treated and untreated Si, 0.5 C charge, 4 C discharge).

This work illustrates how the use of acid-treated Si in the context of Enevate's carbonized Si-carbon electrodes is highly beneficial

for cycling stability.

-

The premium version includes another two patent discussions, plus an Excel list with 50-100 commercially relevant recent patent families.

-

Get a quote to make better informed decisions.

-

Fuel cells (PEMFC / SOFC / PAFC / AEMFC) – electrochemically active materials

-

A platinum-free manganese cathode catalyst complex was made by mixing carbon nanotubes (CNT) and manganese (III) phthalocyanine chloride

(1:2 mass ratio).

The mixture was combined with aniline monomer (2:1 mass ratio) in water and dried at 60°C for 8 h.

The resulting powder was heat-treated at 800°C for 3 h under a nitrogen atmosphere, and dispersed in a solution of Nafion ionomer,

water, and n-propanol.

A graphene dispersion and the catalyst dispersion were injected into separate nozzles. The graphene dispersion was first sprayed onto a FEP (fluorinated ethylene propylene) material, followed by the catalyst dispersion

(ultrasonic spraying, 180 kHz, 10 μm droplets). This process was repeated to alternately layer graphene and catalyst, forming a 100-layer electrode.

Finally, a membrane-electrode assembly (MEA) was created by using this layered structure as a cathode (4 mg/cm2 cathode catalyst loading)

and a Pt/C electrocatalyst as an anode,

hot-pressed onto a polymer electrolyte membrane. Tests were also made with a comparative MEA with 0.2 mg/cm2 Pt-based cathode

catalyst.

A similar initial current density was obtained between the two MEA's. The Mn-based MEA exhibits a current density retention of 91% after 100 h at 0.7 V

as compared to 33% for the Pt-based comparative MEA. Favorable results were also obtained upon use of Fe or Co instead of Mn.

This work illustrates how the definition of a very specific 100-layer graphene-manganese structure enables promising longevity

in cathode PEMFC catalysts.

-

The premium version includes another two patent discussions, plus an Excel list with 50-100 commercially relevant recent patent families.

-

Get a quote to make better informed decisions.

-

Triweekly patent lists for other categories (Excel files are included for premium users)

-

- Lithium metal containing batteries (excluding Li-S, Li-Air): XLSX

-

- Lithium-ion batteries – electrolytes – liquid: XLSX

-

- Lithium-ion batteries – separators: XLSX

-

- Lithium-sulfur batteries: XLSX

-

- Metal-air batteries: XLSX

-

- Na-ion batteries: XLSX

-

Prior patent updates

-

2023-10-31

-

2023-10-10

-

2023-09-19

|