-

International Battery Seminar & Exhibit / Electrolyte Motion Induced Salt Inhomogeneity (EMSI)

Posted on 2025-03-27

-

At the recent International Battery Seminar & Exhibit, Prof. Jeff Dahn highlighted how Si-carbon

composite active materials prepared through monosilane deposition on carbon matrices exhibit very

promising cycling stability.

-

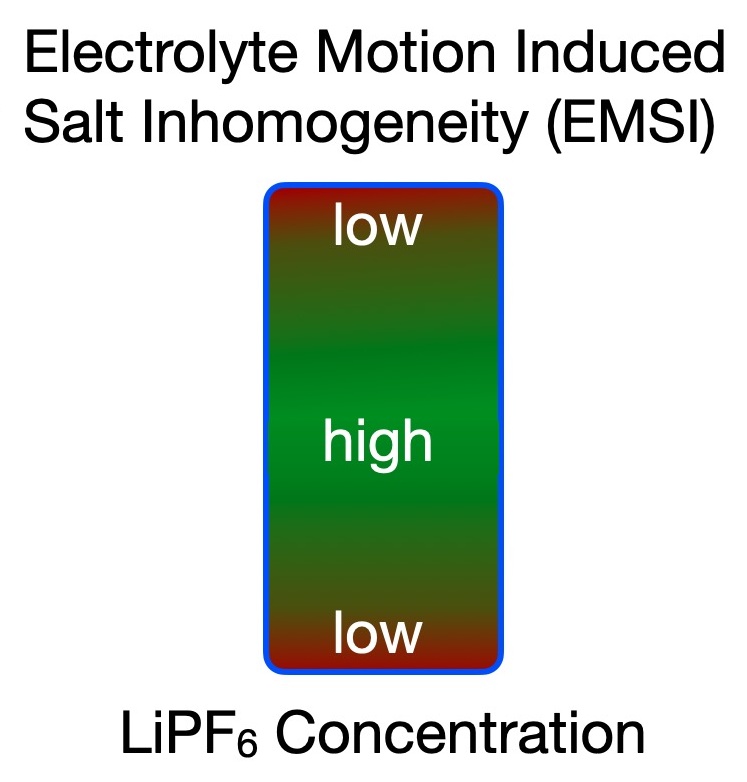

Prof. Dahn emphasized that the quantity of liquid electrolyte has to be very carefully

controlled in such high-energy cells to avoid 'Electrolyte Motion Induced Salt Inhomogeneity' (EMSI),

which can lead to temporary capacity loss (reversible after letting cells rest for weeks) and

lithium plating (risk of irreversible damage).

-

Prof. Dahn referred to work by Dr. Sophie Solchenbach et al. from BMW, who illustrate that

an 'electrolyte pore filling ratio' in Si active material-containing cells of slightly below

1 should be targeted ('sweet spot', as the presence of too little electrolyte also can cause problems).

-

It is therefore very easy to underestimate the performance of Si-based active materials, which

can depend not only on the electrolyte type, but also on the electrolyte pore filling ratio.

-

It is to be watched closely if high-viscosity liquid, semi-solid and/or all-solid electrolytes allow for the avoidance of the undesirable EMSI phenomenon. Avoidance of tight pore size distribution control of materials that are in contact with electrolytes can allow for cost-savings during up-scaling.

-

This post was also published on LinkedIn.

|