-

Li-ion Battery High-energy Silicon Anode Innovation & Patent Review

Posted on 2024-10-04

-

The 2024 edition of the 'Li-ion Battery High-energy Silicon Anode Innovation & Patent Review' by b-science.net is now available.

-

This review is designed for R&D, IP, product management, business development and VC decision makers involved with the prospective

launch of novel Si-based negative electrode materials and corresponding Li-ion battery cells.

-

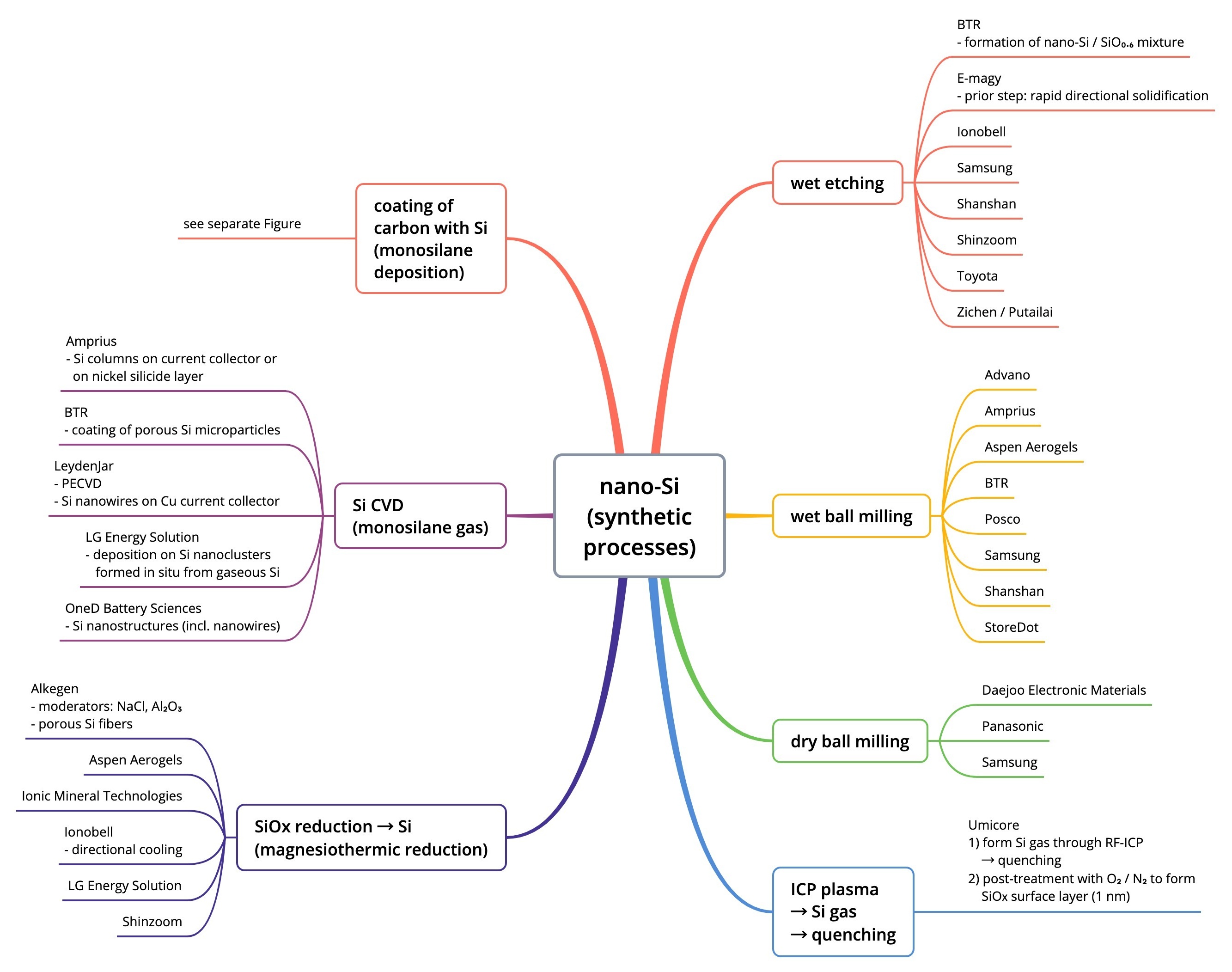

Based on a unique AI-supported approach, this review highlights commercially relevant technical and patent information that has

been identified among the >100k battery patent documents published every year. Divergent technical decisions taken by key

commercial players are visualized (see Figure) and discussed.

-

Opportunities

Recently, nano-scale Si fabrication processes have been developed that for the first time made the deployment of Si-carbon composites feasible

in EV Li-ion batteries with liquid carbonate-based electrolytes, in which Si prospectively contributes the main share to the energy

storage capacity of negative electrodes.

-

State-of-upscaling

Key commercialization breakthroughs have recently happened in terms of the homologation by Panasonic of Si-carbon composite

active materials by Sila Nanotechnologies and Nexeon for future liquid carbonate-based EV Li-ion batteries. In addition,

Group14 Technologies reported 5 binding purchase agreements (total: USD >300M) for its Si-carbon composite active material,

while OneD Battery Sciences has assembled a consortium to build 2 co-located, vertically integrated monosilane / Si-carbon composite plants in North America.

-

Around this flurry of activity in relation to the monosilane-based formation of nano-scale Si, multiple alternative Si

formation approaches are pursued based on the shared target of reducing costs without sacrificing performance or safety.

-

Challenges

The emphasis of Si-carbon composite makers on producing ‘drop-in’ replacement products for graphite active materials has for now paid off in

EV applications, because a drop in the slowest roll-to-roll process step due to the introduction of Si-based active materials has been avoided

with this approach (similar speed of negative electrode deposition on current collector foil between graphite and novel Si-carbon composite active materials).

-

Nonetheless, all players in this field have to make up their mind on the extent to which they wish to develop their materials for future

semi-solid / all-solid Li-ion battery cell types and/or dry electrode processes that have not yet captured massive market share,

yet have already reached commercialization thresholds that cannot be ignored (semi-solid electrolytes: EUR 5.2B gigafactory

construction by ProLogium Technology, dry electrodes: industrial use by Tesla for graphite-based electrodes).

-

Competitive Threats

The key competitive threat for negative electrodes based on Si-based active materials are Li metal negative electrodes.

A corresponding deep dive chapter is therefore included in this review: 'Interfaces: Lithium Metal Electrodes – Polymer-based Electrolytes'.

-

Preview

The preview to this review including table of contents is available here (PDF).

-

This post was also published on LinkedIn.

|