-

-

Many thanks to TechBlick for a having put together a great virtual conference last week on next-generation battery product development efforts & market needs!

Thanks for the opportunity to talk about solid electrolyte film formation processes.

-

To achieve successful upscaling of semi-solid and all-solid-state Li-ion batteries, a careful balance has to be achieved between process innovation and risk,

in addition to selecting the right active and electrolyte materials.

-

Points to be considered:

-

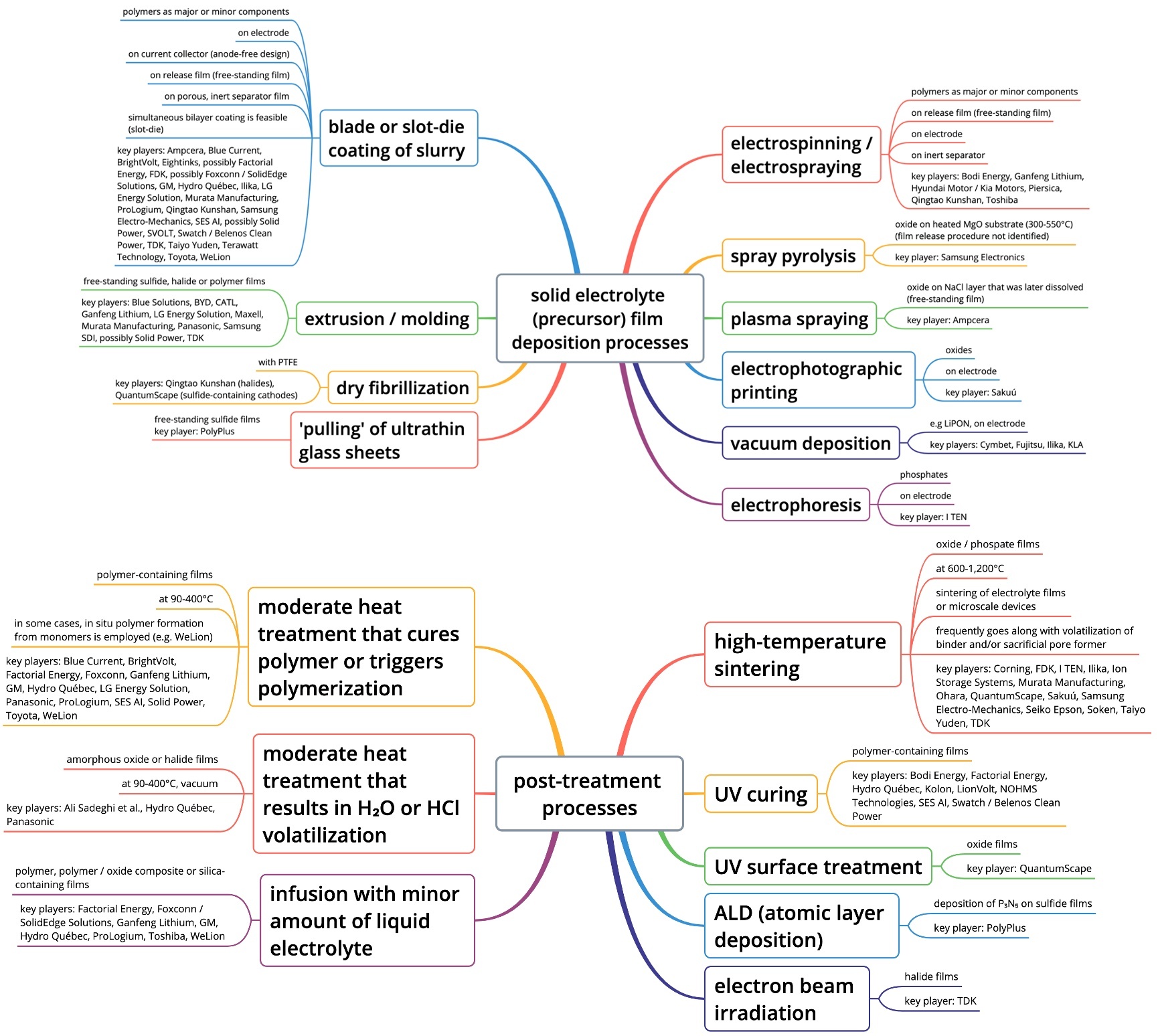

Process is already used to produce commercial batteries? Frontrunners: blade / slot-die coating, extrusion, vacuum deposition (microscale cells), electrophoresis (microscale cells).

-

Can all kinds of materials be mixed and matched without substantial process refactoring, including to form bi-layer electrolyte structures? Frontrunners: blade / slot-die and similar coating processes, electrophotographic printing.

-

Avoidance of solvents? Frontrunners: extrusion, molding, dry fibrillization, electrophotographic printing, 'pulling' of glass sheets, plasma spraying, vacuum deposition (microscale cells).

-

Very tight control of nano-architecture at <10 μm film thickness? Frontrunners: electro-spinning / electro-spraying, vacuum deposition (microscale cells).

-

Preview of our 'Solid-state / Semi-solid Li-ion Battery Innovation & Patent Review'.

-

This post was also published on LinkedIn.

|